Freestanding coolers

Freestanding coolers

Freestanding coolers

Dual circuit coolers are individually custom-designed and developed by our team to suit the intended location. You can thus be sure to reach the optimum temperature on site at all times.

Our complete portfolio of cooling networks is constructed exclusively by us ourselves. It is also no problem for us to manufacture even large dual circuit coolers in our in-house soldering furnaces and using several 3D-CAD systems and our own cooler calculation programs specially developed by us. You have some special requirements regarding our dual circuit coolers? No problem. For example, on request we also equip our cooling systems with a hydrostatic fan drive.

Best performance - even in extreme conditions

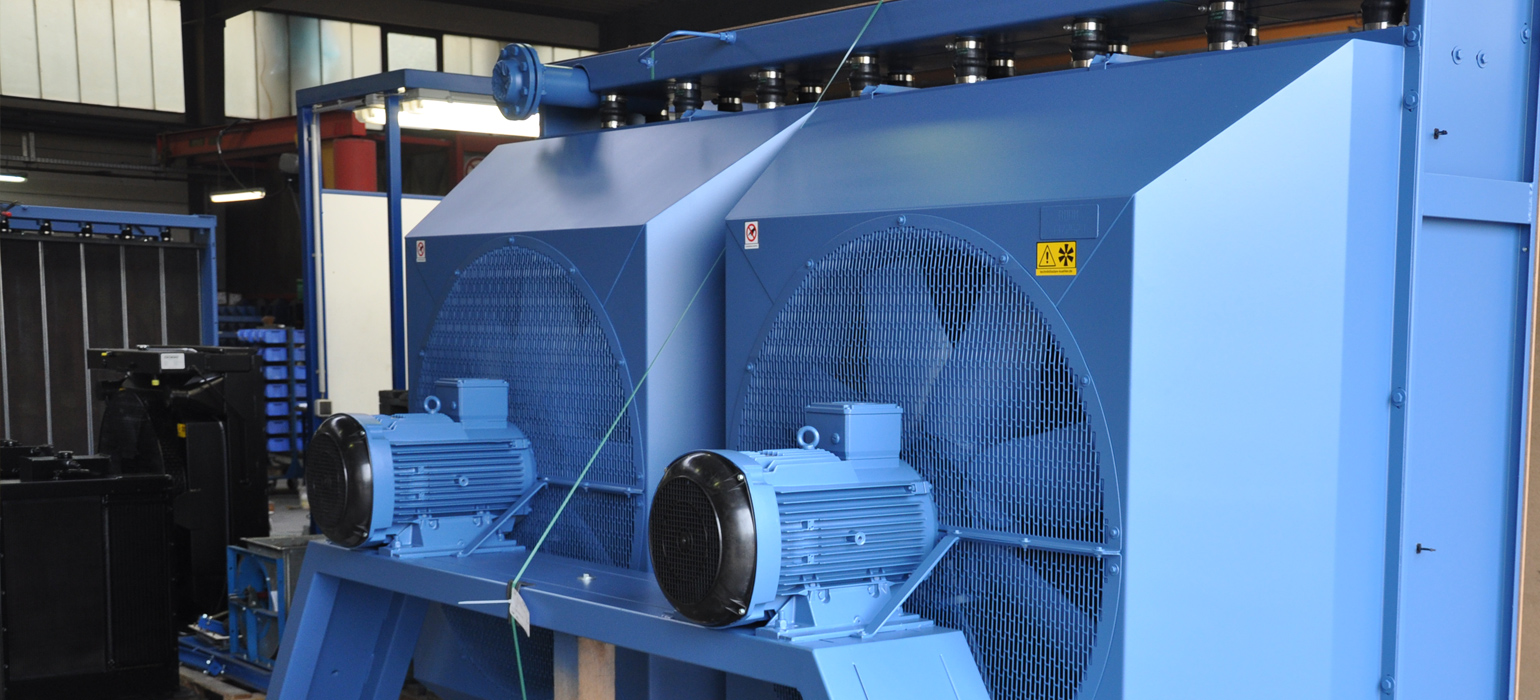

When top performance is called for, our freestanding fan blade coolers in partial block design come into operation.These high-efficiency cooling systems stand out due to their particularly long operating times and are tailor-made to meet your individual needs and application.

The freestanding coolers are specially designed for the cooling of large diesel motors for power generators, no break system generators and pump units in hospitals and airports, on cranes, ships and oil platforms. They are equipped with bellows hoses to ensure a reduced thermoelectric emf as well as VA hose clips with spring tension element. In addition, our axial high performance fans are equipped with electric motors with power reserves.

We manufacture our freestanding coolers in partial block design - these separable constructions are thus optimally suited for difficult installation situations. In the event of any damage, it is possible to exchange individual blocks within a short space of time. The individual cooling elements are available in 2 different arrangements: side-by-side or back-to-back.

Certified quality

Every cooling system runs through our comprehensive LTPT-programme (Long Time Proof Test) for at least 12 hours before it is dispatched. All parts conveying water are tested by means of a double-pressure test.

Depending on their later use, our electric motors are installed with different IE efficiency classifications. In accordance with the area of operation they are intended for in the future, it is possible to build the coolers with either high performance cooling elements or cooling lamellas insensitive to dirt. In addition, all high performance fans are equipped with blades where the angle can be adjusted when the blades are not in motion.